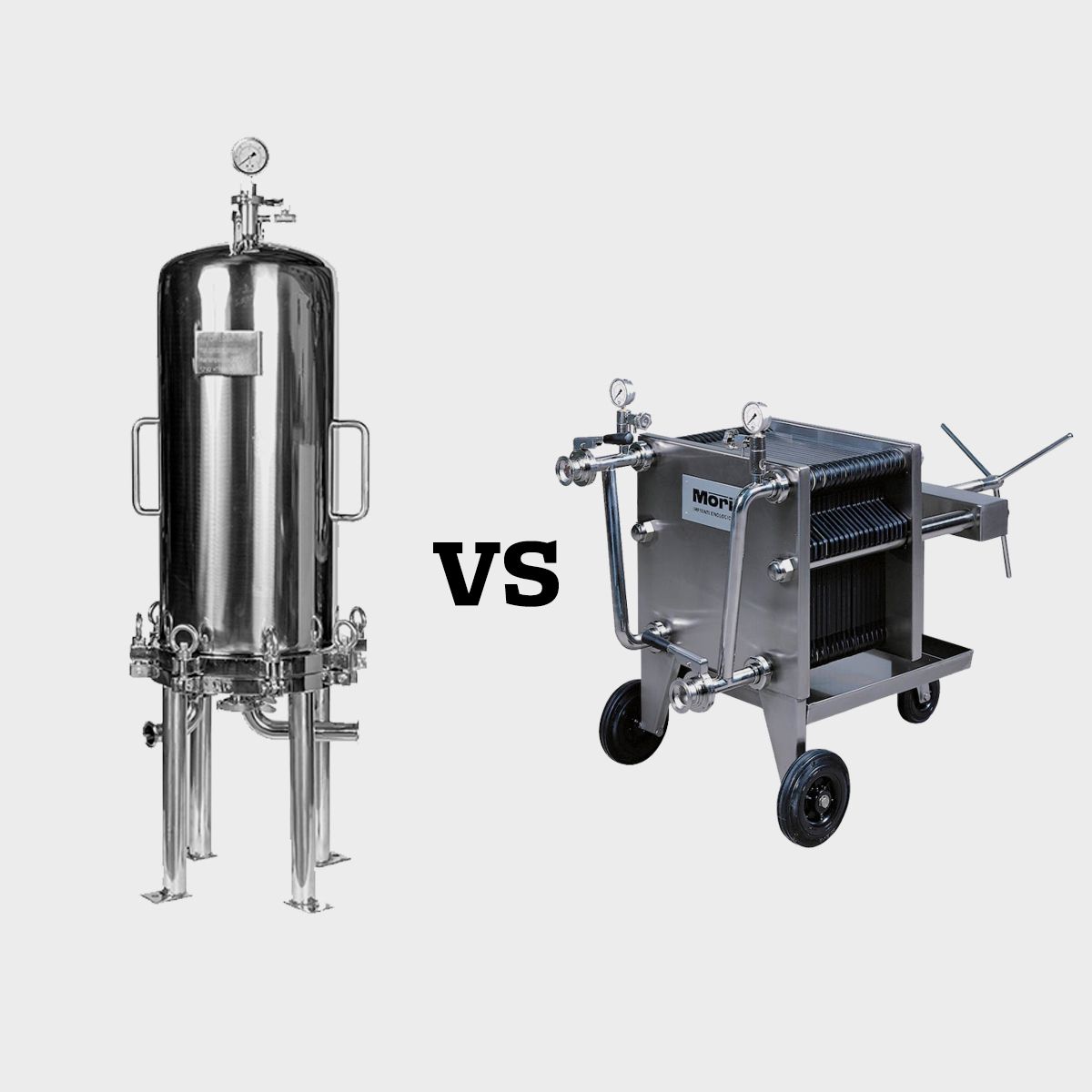

Lenticular vs. Plate & Frame Filtration

People often ask us about the difference between lenticular filtration and plate & frame filtration. Which one is superior for most applications? While there's no correct answer to this question, we can dive into the details about how they're different. Hopefully you'll come to a conclusion about which suits you best. If you're not familiar with either, let's have a quick overview:

Plate & Frame Filters

As a technology, plate & frame filtration is older than lenticular. Its roots date back to the mid-1800's. Its function and design have been refined over the years. Still, the commercial units available for sale today are not much different from the ones available in, say, the 1980's.

Plate & Frame filters are made up of two parts:

- The frame, which is usually made of stainless steel

- A variable number of plates hanging from the frame. The plates may be made of Noryl, Polypropylene, or stainless steel.

Before loading the frame with filter sheets, users loosen the large central screw and spread the plates apart so that they can place filter sheets between each of the plates. Once the sheets are loaded, the user tightens the large central screw to close the press tightly. Closing tightly should minimize dripping from the sheets. Sheets will hang out of the plates slightly. Some dripping of product is inevitable and expected.

The product to be filtered typically enters through a port in the front face of the system and exits on the same side unless you are using a crossover plate (more on crossover plates later).

Although filter sheets can come in a variety of shapes and sizes, the beverage industry has largely settled on square filter sheets that are designated either “40 x 40” or “20 x 20”. These numbers denote the size of the sheet in centimeters. So, a 40 x 40 sheet is 40 cm x 40 cm square.

Lenticular Filters

Lenticular filters are a much more recent invention. They were actually designed to address some of the problems that plate & frame filter users face. We'll go more into those problems later, and how lenticular filters solve them.

A lenticular filter housing is a stainless steel vessel. If you're familiar with cartridge filtration, the design is quite similar. Lenticular filters are made up of a base that holds the lenticular modules and a top dome that covers the modules and seals the entire system.

In case you're curious why they're called “lenticular” filters, a lenticle is something that is shaped like a lens. If you look at a lenticular filter module you'll notice that they look like a bunch of lenses stacked on top of each other. Each of these lenses is called a lenticular cell. Hence, they're called lenticular filters because of their shape. The picture below is of a 16-cell lenticular module.

In a plate & frame system it's the plates that hold the sheets and direct the flow of liquid. In lenticular systems, on the other hand, it's the lenticular modules themselves that provide structural support. Lenticular modules feature a skeleton made of polypropylene that holds the lenticular cells and provide the structure. The cells themselves are made of the same material found in filter sheets.

Since the lenticular modules provide most of the support for the filter media, the stainless structure is more or less just dumb plumbing. This means there are far fewer parts in a lenticular housing than in a plate & frame setup. Much of the infrastructure is in the lenticular modules themselves.

Do either plate & frame or lenticular filters offer better filtration?

We've already noted above that both plate & frame and lenticular filters are made up of the same media. This media is usually some combination of the following:

- D.E., or diatomaceous earth

- Cellulose—a fancy way of saying paper

- Perlite, which is composed of a volcanic glass and is often used as an alternative to D.E.

- Carbon, which is most often used for chlorine removal, and odor or color removal in clear spirits of ethanol extraction applications

Most filter manufacturers will offer the exact same media in both filter sheet or lenticular modules. Just the form differs. As a result, there is no real difference in the quality of filtration you will get from either lenticular or plate & frame filtration. It's the exact same media.

What are the pros of plate & frame relative to lenticular?

Plate & Frame Pro: The crossover plate option

A crossover plate is a special plate that you can add to your plate & frame to increase its versatility. To know why it's useful, it's helpful to know the following: you can only use one grade of media in a basic plate & frame system. For example, if you're using coarse-grade sheets you must use the same coarse-grade sheets in every plate. You can't mix in fine-grade sheets and expect your product to pass through both. The product will just bypass the fine-grade sheets altogether. Adding a crossover plate, though, changes things.

If you have, say, a 30-plate frame, you can add a crossover plate in the middle and it will effectively split the system into two 15-plate sections. Product will pass through the first set of 15 sheets, then it will hit the crossover plate where they will cross over into the second set of 15 sheets. It will pass through both sets of sheets in series.

In short, with a crossover plate you can use different filter grades in a single pass, whereas you'd normally need to run coarse and fine filtration in two separate passes.

The reason this is a pro relative to lenticular filtration is that there is no similar mechanism for lenticular filter housings. If you want to run two different grades in a single pass, you need a second housing.

Plate & Frame Pro: The media price

The main pro of plate & frame filtration is the low cost of the plate & frame media. Keep in mind: it's a pretty big pro. Let's analyze further.

To make sure we're comparing apples to apples, let's compare by surface area. A standard 16-cell 12" lenticular module has a usable surface area of about 1.8 m². A 40 x 40 filter sheet has a usable surface area of 0.16 m². Thus, it takes about 12 filter sheets to make up the same surface area as a lenticular module. We'll use a sterile grade of filter media for our comparison. Filtrox AF ST 130 sheets are $2.96/sheet as of today, so 12 of them will cost about $35.52. Meanwhile, a 12" lenticular module of the same grade and the same surface area is $260. So the cost lenticular media is over 7 times higher for the same product.

That's a huge price difference. If upfront media price is the only factor, I wouldn't blame you for closing this tab now, clicking “Buy” on the plate & frame filter in your cart, and never looking back. But the fact is, we've sold fewer and fewer plate & frame filters year over year. Meanwhile we've sold more and more lenticular filters over the same time period. So what gives? Let's dive into the pros of lenticular.

What are the pros of lenticular relative to plate & frame?

Lenticular Pro: User ergonomics

The main pro of lenticular filters is, in a word, ergonomics. Anyone who has loaded and unloaded a plate & frame filter will tell you that it's messy, labor-intensive, and unintuitive. Closing the frame tight enough to minimize dripping (not eliminate, minimize) requires a lot of strength, and more strength is required for greater numbers of plates. At 60+ plus plates, it makes sense to consider adding on a hydraulic pump to close the filter. The strength required to close a 60-plate frame is just too great for most cellar workers.

And good luck teaching the new guy how to properly load a plate & frame filter so that the sheets are all facing in the correct direction. Plate & frame filters are extremely unintuitive, and require a good amount of training to operate properly.

Meanwhile, lenticular filters are simple. To load lenticular modules you remove the top housing, load modules onto the center post, and screw down the top nut. To unload you just reverse those steps. It doesn't require any complex diagrams to understand, and pretty much anyone will just get it intuitively without too much confusion.

Lenticular Pro: Lower product loss & less exposure to air

Plate & frame filters are open to the atmosphere, and can drip, as noted previously. Both factors lead to product loss. This is one of the main factors that lenticular filters were designed to address. Since lenticular filters are completely sealed, there is no product lost to dripping or evaporation.

There's also less exposure to air in a sealed lenticular system. If you're concerned about picking up dissolved oxygen, or if you're filtering something with high alcohol content and want to avoid having the fumes in an enclosed space, lenticular is a no-brainer.

Lenticular Pro: The media price?

Above we noted that lenticular filters are quite a bit more expensive than filter sheets. If you’re comparing upfront costs that’s objectively true. However it doesn’t tell the full story.

Lenticular modules are hardier than filter sheets. The modules can withstand multiple regeneration cycles, and can be stored between uses. Filter sheets are single-use only. When you're done with a batch, you're done with the sheets.

Knowing that plate & frame filters are more time-consuming to use, lead to greater product loss, and can't be regenerated and reused like lenticular media, the question of cost becomes more difficult to answer definitively. We'd go so far as to say it's a toss-up.

So which do you choose?

If you've been following along this far, you may have realized that the answer isn't quite so cut-and-dried. Both lenticular and plate & frame have their strengths and weaknesses. Still, for facilities who don't have either, a lenticular filter probably makes the most sense. As noted previously, we have already seen a shift in customer preference toward lenticular, mostly for the reasons noted above.

That said, if you have a plate & frame filter already, know how to use it, and aren't put off by the “downsides”, there's really no reason to toss it aside for a lenticular filter. However, when it comes time to replace it, you'll probably want to replace it with lenticular.

If the upfront media cost is the #1 concern, then buying a plate & filter makes sense. The media is certainly cheaper. Of course, remember to take everything into account: product loss, exposure to air, cost of labor, as well as the fact that filter sheets are single-use, while lenticular modules can be regenerated and reused.

Got any more questions about lenticular vs. plate and frame filtration? Let us know! We love talking filtration.

- © 2024 TCW Equipment, LLC

- Phone: (707) 963-9681

- Monday–Friday, 8–5 pm PT