The Best Mash Pumps for Breweries

Transferring mash in a brewery can be tricky. It'd be nice if you could just open the valve from a hot vat of mash, turn on any old pump, and walk away, confident that the mash will be moved without issue. It ain't that easy, of course. Most pumps can easily move liquids that are:

- Cool or room temperature

- Water-like in consistency

- Free of solids and abrasives

How does beer mash meet stack up to those ideals? Well, unless you pump it cool, mash can be nearly boiling in temperature, oatmeal-like in consistency, and it most definitely will have plenty of solids, so nope, nope, aaaaaand nope.

Let's talk about a few different styles of pump that make a great mash pump for breweries. First off, though, let's make a wish list for a mash pump:

Mash Pump Wish #1: We'd like it to be self-priming

Pumps that are self-priming do not need to have liquid flowing freely to the inlet. They will suck liquids some distance if the pump is dry at first. Even the most powerful vacuum in the world can only suck liquid some 30 feet or so, so it's always best to keep the pump as close to the source tank as possible, and definitely a good idea to have any solids move towards the pump by gravity. Pumps like to suck up liquids and leave solids behind, so you'll want to make it easy for solids to flow naturally to the inlet. Consider this as you design your tanks, facility, and general processes.

Mash Pump Wish #2: We'd like it to work at high temperatures

Many pumps are cooled by the liquid they're pumping. If the liquid they're pumping is hot, well, that's not cool. The end result is usually that seals become damaged and the pump ends up leaking or otherwise self-destructing, leaving you down one good pump and up one grumpy maintenance person.

So, we'd like a pump that can easily move hot liquids. Boiling or near-boiling, ideally.

Mash Pump Wish #3: We'd like it move thick liquids

Thick, grainy mashes are more difficult to pump than something that has a water-like viscosity. Any time you're pumping a liquid that is higher viscosity than water, you'll want a pump that's capable of pushing liquids at higher-than-average pressures.

Mash Pump Wish #4: We'd like it to handle solids in suspension

“Solids in suspension” just means liquid with some solids in it. Mash can have a high amount of solids in suspension.

Some pumps are more sensitive to solids in suspension than others, so its also important to understand what the largest solid would typically be. Many pumps—particularly air-operated double diaphragm pumps—will list the maximum solid they're capable of moving without clogging.

Mash Pump Wish #5: We'd prefer it to have dry-running capability

Dry-running means a pump can run with no liquid in the head. Not all pumps can do this. Many will overheat and self-destruct if run dry.

For most users, the ability to run dry is not a make or break one. As long as everyone on your team knows that you can't run the pump dry and takes the appropriate precautions, it's fine. Still, every now and again a situation comes up. Maybe the new guy wasn't listening during training and his attention wanders while the pump is running. He starts responding to a “Best Boots?” thread in /r/TheBrewery with his hot take. Before he knows it, the pump seals are smoking away. That's why dry-running is definitely a nice to have feature.

So, now we have our wish list made up, let's look at a few options and see how they compare:

The Flexible Impeller Pump

Flexible impeller pumps are often the first stop as a dedicated brewery mash pump. They tick many of the boxes on our wish list, though they can't run dry. They are self-priming and can pull very good suction—particularly when pre-wetted with a bit of liquid. They can pass large solids, usually up to about 1/4-1/2 the size of the inlet. They can move thick liquids with ease, and are often use for syrups and the like. High temperatures, though, well…they can be a flexible impeller pump's kryptonite.

The impeller in a flexible impeller pump is made of rubber—neoprene, EPDM, or nitrile, usually. Rubbers often swell up at higher temperatures. This can be a problem, since the flexible impeller is precisely sized to fit in the head. Too much swelling and it won't fit inside the pump head as designed. As a result, it will create extra heat and friction and tear itself apart. There is a solution, however.

Jabsco makes special impellers that are cut smaller than standard impellers. They are designed specifically for use at high temperatures. When they swell, as they inevitably will at high temps, they take up the available space and pump more efficiently. They actually like high temperatures, in other words.

The downside to this is that they are less efficient at standard temperatures. That means that if you go with a flexible impeller pump as your mash pump you will want to either:

- Cool the mash down before pumping it

- Get the high temperature impeller and use the pump mostly for high temperature jobs

Nonetheless, the low relative price of flexible impeller pumps and their general versatility makes them an attractive choice—particularly as a first mash pump. Give us a call about the high-temperature impeller option.

Entry-Level Flexible Impeller Mash Pump: Jabsco SQN 20, 20 GPM

Mid-Level Flexible Impeller Mash Pump: Jabsco SQN 50, 50 GPM

Premium Flexible Impeller Mash Pump: Jabsco SQN 100, 100 GPM or SQN 130, 130 GPM

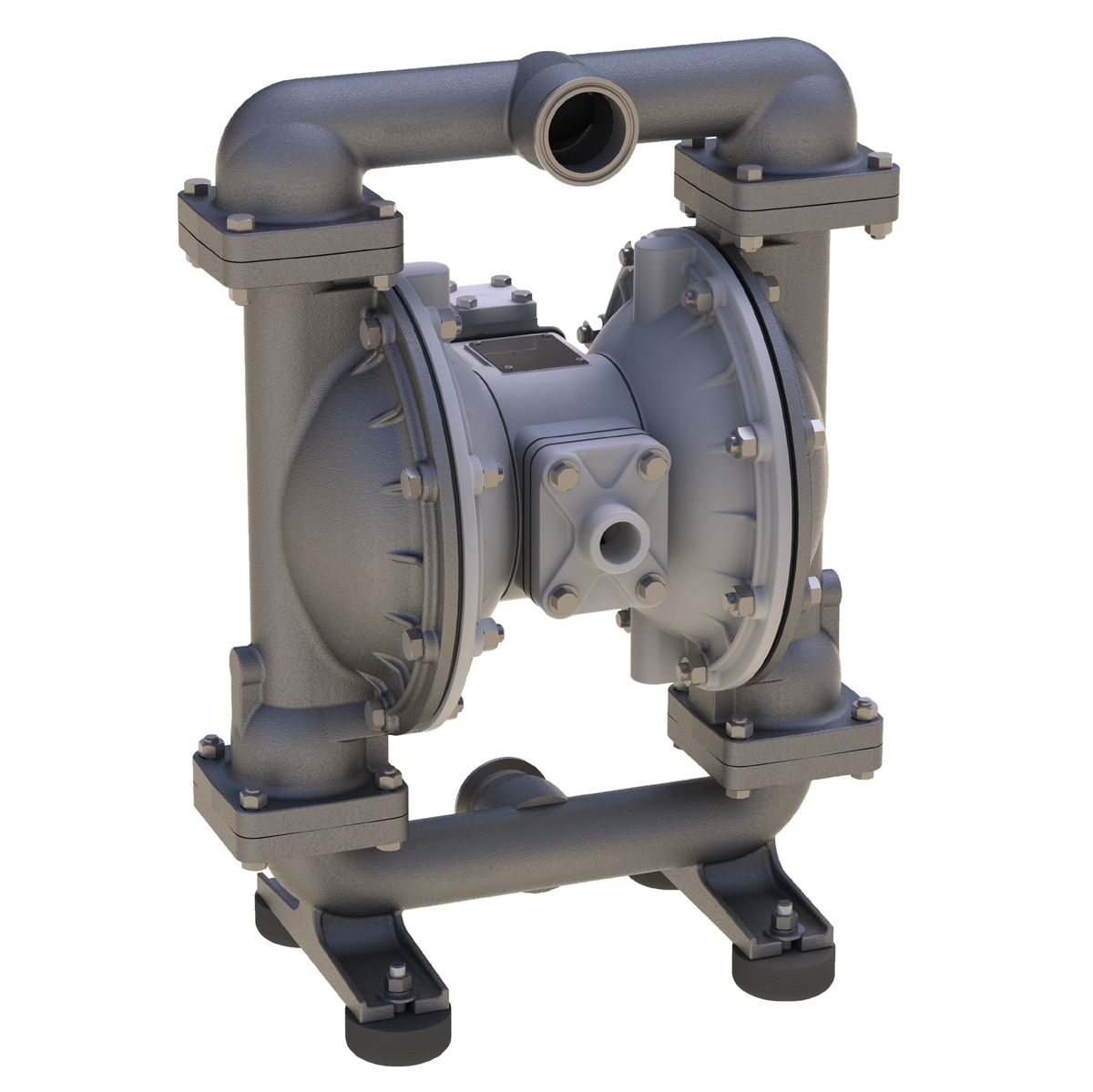

Air-Operated Double Diaphragm Pumps

We've written about AODD pumps before. They're a great choice for breweries in general because of their gentle pumping properties. They can also move mash when sized appropriately. Depending on the consistency of the mash, and the largest solids you expect to move with it, AODD pumps can be a good choice. A 2" TC pump like the Sandpiper T15 is large enough to move solids 1/4" in diameter.

Some customers have had luck with even smaller pumps, like the SimpleWine 43. With a 1" inlet/outlet it can move solids up to about 1/8" in diameter. This is probably about as small as you'd want to go, though.

AODD pumps can move very hot liquids with ease, so hot mash is no problem. Likewise, they are self-priming, and can pump viscous liquids, so they tick all the boxes. So long as you have a large enough air compressor, AODD pumps are a solid choice.

Entry-Level AODD Mash Pump: SimpleWine 43, 43 GPM

Mid-Level AODD Mash Pump: Sandpiper T15, 106 GPM

High-End AODD Mash Pump: Sandpiper T20, 200 GPM

RPD Pumps

When a facility is ready to get serious—and has the budget to do so—an RPD pump is usually the way they go.

RPD pumps like Ampco's ZP1 series tick all the boxes in our wish list with ease. Boiling mash? They can pump liquids up to 300 degrees Fahrenheit. They're self-priming, reversible, and can move large solids in suspension.

Their high price tag can be off-putting at first, but they epitomize the “buy once, cry once” philosophy. If you're considering the cost of pump downtime and maintenance, these pumps become a clear winner. They are extremely sturdy, and with their dry-running capabilities, you won't be kicking yourself if you accidentally get distracted while pumping and don't notice that the lines have run dry.

Entry-Level RPD Mash Pump: Ampco ZP1-30, 35 GPM

Mid-Level RPD Mash Pump: Ampco ZP1-40, 46 GPM

Premium RPD Mash Pump: Ampco ZP1-60, 90 GPM or ZP1-130, 150 GPM

Peristaltic Pumps

If we're talking about gentleness, Ragazzini peristaltic pumps absolutely take the cake. They're so gentle that they're used as blood transfusion pumps in hospitals. And yet, they're so durable that they're used in mining/construction operations to pump rock slurry and concrete that would make mincemeat of other pumps.

Unlike any of the other pumps we've talked about so far, peristaltic pumps have no seals, no check valves, and no problems moving heavy solids. We discuss their many virtues in our Guide to Peristaltic Pumps.

Ragazzini's peristaltic pumps can pump huge solids (even whole hops, when sized appropriately), and can suck liquids from about 30 feet away. That's way more than just about any other pump.

The only thing to be aware of with peristaltic pumps is that—as with flexible impeller pumps—the main wear part is rubber. The peristaltic tube is made of natural rubber that has a maximum temperature rating of 185 °F. That means boiling mash is a no-go.

Still, it's other benefits: dry running, reversibility, gentleness, and general simplicity, make it a strong contender for top mash pump.

Entry-level Peristaltic Mash Pump: Ragazzini Rotho MS1, 25 GPM

Mid-level Peristaltic Mash Pump: Ragazzini Rotho MS2, 55 GPM

Premium Peristaltic Mash Pump: Ragazzini Rotho MS3, 90 GPM

Conclusion

So now that you have a lay of the land we hope you have some idea of which direction will work best for your facility. If not, feel free to give us a call. We love talking mash pumps.

- © 2024 TCW Equipment, LLC

- Phone: (707) 963-9681

- Monday–Friday, 8–5 pm PT